Concrete flatwork is essential for modern exterior and interior spaces, requiring a systematic approach that balances planning, material selection, expert installation, and regular upkeep. Experienced professionals can provide expert solutions and industry expertise. By integrating proven techniques and staying current with technology, every phase of a concrete project can deliver value, resilience, and visual distinction, ensuring long-lasting flatwork and property appeal.

Planning and Design Considerations

Concrete flatwork projects require meticulous planning and design to anticipate challenges and optimize functionality. Site evaluation involves analyzing soil stability, drainage routes, and structural loads to reduce shifting risk. Climate adaptation consists in tailoring designs to local weather conditions, such as freeze-thaw cycles or high rainfall. Use requirements include determining thickness and reinforcement based on anticipated traffic, with commercial settings typically requiring thicker slabs. To explore professional solutions and best practices for your next flatwork project, click here. Choosing the right contractor can significantly affect long-term durability and performance.

Material Selection and Mix Design

Material selection and mix formulation significantly influence concrete flatwork’s strength, finish, and lifespan. Choose a mix tailored to project needs, such as higher compressive strength for driveways or fast-setting blends for time-sensitive jobs. Quality aggregates, such as rounded or angular stones, determine the slab’s appearance and stability. Incorporate chemical or mineral admixtures for enhanced setting times.

Proper Installation Techniques

Concrete durability relies on professional installation methods. Subgrade preparation, formwork, reinforcement, pouring, and finishing are all crucial steps. A compacted and leveled subgrade is essential for limiting settlement and cracking. Robust forms define the slab’s shape and dimensions, while steel rebar or wire mesh provides tensile strength. Pouring and finishing should be even and quick, avoiding cold joints and overworking. Curing should be kept moist and stable for at least seven days to enhance final strength and minimize shrinkage cracks.

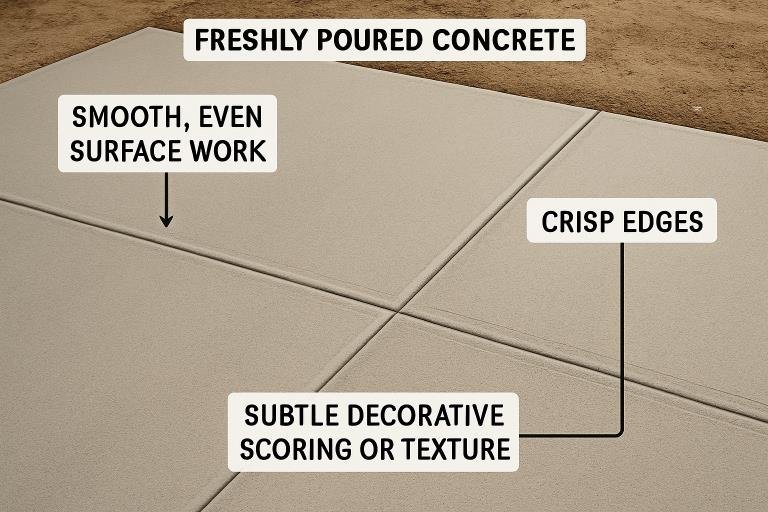

Decorative Finishes and Aesthetic Enhancements

Decorative flatwork options in concrete offer a high-end appearance without compromising performance. Patterned mats imprint textures, while colored concrete can match landscapes or architectural colors. Surface washing or chemical treatments expose aggregates for slip resistance. Mechanical polishing produces smooth surfaces ideal for modern patios and commercial interiors.

Maintenance and Long-Term Care

Concrete flatwork requires regular maintenance to maintain its structural integrity and aesthetic appeal. This includes cleaning, sealing, crack repair, and resurfacing. Regular sweeps and washing remove debris, while high-quality sealers protect against water penetration, stains, and freeze-thaw cycles. Crack repair using flexible sealants or epoxy injections prevents expansion. Modern resurfacing systems can restore appearance and function without total replacement.

Sustainable and Eco-Friendly Practices

Eco-conscious construction, utilizing sustainable methods and materials, is increasingly prevalent in building projects. This includes using recycled materials, formulated concrete mixes, and energy-efficient production methods. These practices conserve resources, reduce landfill waste, and promote groundwater recharge. Additionally, sourcing materials from renewable energy sources supports the green building movement.

Technological Advancements in Concrete Flatwork

New technologies like 3D printing, self-healing concrete, and smart concrete are revolutionizing construction and design. 3D printing offers design freedom and construction efficiencies, self-healing concrete enhances durability and reduces repair costs, and smart concrete integrates sensors for real-time data on structural health and temperature.

Learn more about the impact of these advancements at this study on navigating the digital chain in concrete 3D printing.

When best practices, innovative methods, and diligent care converge, concrete flatwork delivers exceptional durability and eye-catching aesthetics, ensuring value and lasting appeal for residential and commercial properties.