Key Takeaways

- Thorough water main testing protects public health and infrastructure.

- Regulations demand precise procedures for testing new and existing lines.

- Advances in pressure testing equipment lead to greater efficiency and reliability.

- Regular inspection and testing help detect silent leaks and prevent costly repairs.

- Educating crews on modern testing best practices is crucial for both large and small projects.

The Role of Water Main Testing in Infrastructure Health

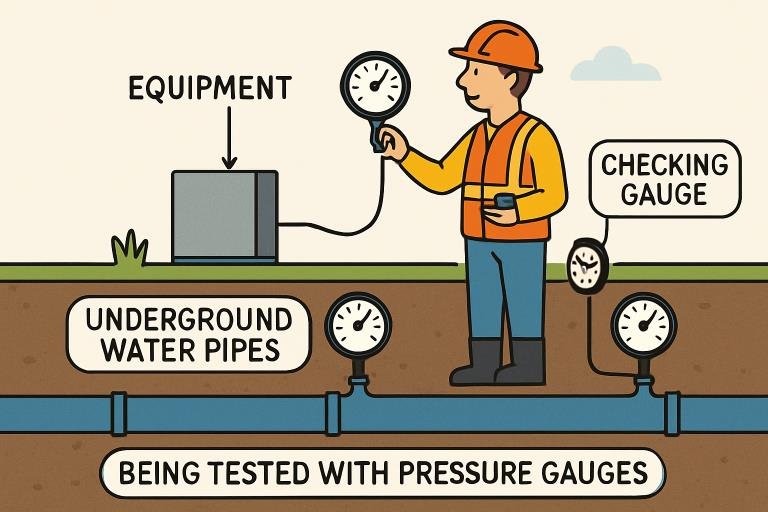

Underground water mains are vital for city health, as they supply clean water to homes and businesses. Even small, undetected leaks can cause contamination or structural issues. Reliable testing, including tools such as a hydrostatic test pump, is crucial for ensuring safety and the longevity of infrastructure. It helps identify problems early, preventing failures and service disruptions. As cities grow and infrastructure ages, accurate testing becomes increasingly critical. Poor testing risks undetected leaks, erosion, and large failures, threatening public health and increasing repair costs. The EPA emphasizes the importance of timely leak detection to maintain water quality and reduce costs. Regular testing also prevents road collapses or sinkholes caused by hidden leaks, utilizing advanced technology to enhance infrastructure resilience and community safety.

Meeting High Standards: Pressure Testing Requirements

Public utilities adopt stringent guidelines for pipe testing, modeled after the American Water Works Association (AWWA) standards. These protocols demand thorough documentation, minimum pressure thresholds, and leak tolerance levels for both new and rehabilitated lines. Many municipalities require testing crews to use calibrated gauges and, in some cases, obtain independent verification before lines can be put into service. By standardizing the process, the risk of errors is minimized, and public confidence in water systems is maintained.

Common Challenges with Underground Water Mains

Subterranean pipelines are constantly under threat from shifting earth, environmental stresses, and street traffic. Modern installations must accommodate pressure fluctuations, ground movement, and joint integrity. Even professionally installed mains can develop hairline cracks at joints or bends due to unexpected soil settling or temperature swings. If left unchecked, these minor imperfections eventually lead to a loss of pressure, structural undermining, and increased contamination risks. For aging infrastructure, routine retesting is every bit as critical as it is for new mains.

Advances in Underground Pipeline Testing

The latest generation of test pumps and software-driven monitoring platforms streamline pressure testing and result recording, saving time while reducing human error. Remote sensors transmit real-time data to central dashboards, allowing field crews and supervisors to respond instantly to anomalies. These advancements have transformed leak detection, enabling faster and more comprehensive analysis, as well as more effective maintenance planning. Industry research published by WaterWorld highlights ongoing investment in technology as crucial for preparing water systems for future demand and urban complexity.

Protocols for a Successful Water Main Test

- Ensure all service connections are securely closed, isolating the area to be tested from the network.

- Fill the system with clean, potable water and eliminate any trapped air pockets for consistent results.

- Attach calibrated testing equipment, set the target pressure, and gradually increase to the specified limits.

- Maintain the pressure for at least two hours (or as required by local standards) while monitoring all gauges.

- Record and immediately address any pressure drop; locate leaks using sensors or noise correlation equipment as needed.

- Document all procedures, results, and corrective actions for submission to municipal authorities or clients.

Methodical adherence to these steps ensures both compliance and a verifiable record of safety, reducing liability and building project trust.

Practical Tips for Field Technicians

- Verify that all connections and gauges are secure and functioning before starting the test.

- Observe pressure readings continuously; catching even minor fluctuations prevents delayed repairs.

- Clear the immediate test area of vehicles and non-essential personnel to avoid disturbances and ensure safety.

- Provide thorough training on emergency valve shut-off procedures to all technicians involved in the test.

- Take time during review—hasty analysis can miss data points, leading to overlooked leaks or compliance issues.

Looking Ahead: The Future of Water Main Maintenance

As urban populations swell and infrastructure ages, cities are investing in predictive analytics, remote monitoring, and advanced leak detection to stay ahead of problems. Cloud-based systems will soon enable continuous tracking of water main health, allowing for the detection of leaks before they impact the public. Meanwhile, emerging industry standards and ongoing crew education ensure that pressure testing remains an integral component of water system management. By embracing innovation and adhering to proven protocols, municipalities can provide clean, reliable water for generations to come, meeting tomorrow’s challenges with confidence.