The Role of Pump Bases in Industrial Applications

Pump bases are foundational elements in industrial pumping systems, designed to provide secure and stable mounting for pumps and their drivers. They play a critical role in reducing vibration, ensuring proper alignment, and safeguarding the pump system’s long-term operational efficiency. High-quality pump base installation is indispensable for reliable operation, whether in water treatment plants, chemical processing facilities, or commercial HVAC systems. The link between installation quality and system reliability cannot be overstated—improper installation can introduce misalignment, increase maintenance needs, and limit the lifespan of critical equipment. For details on choosing optimal pump solutions and consulting with pump experts, resources like https://cbeuptime.com/grundfos/ can provide valuable guidance. Proper selection, precise leveling, and secure anchoring of pump bases help prevent premature wear and costly downtime. Regular inspections and maintenance of the base also ensure continued alignment and vibration control, supporting overall system performance.

Key Materials and Manufacturing Considerations

Selecting the right material for pump bases is crucial for performance and longevity. The most common materials are steel, concrete, and advanced composites. Steel offers high strength and is preferred in environments where rigidity is essential. Concrete bases are ideal for large pumps when vibration damping is a priority. Composites, though costlier, combine strength and chemical resistance, making them suitable for highly corrosive or sensitive applications.

Corrosion resistance and durability are key factors influencing material selection. Stainless steel and coated alloys deliver excellent protection against rust and chemical attack, significantly extending the base’s service life. Environmental considerations—such as potential for ground contamination, energy required for manufacturing, and recyclability—are increasingly influencing material selection, pushing many facility managers toward more sustainable options.

Installation Procedures: Step-By-Step Insights

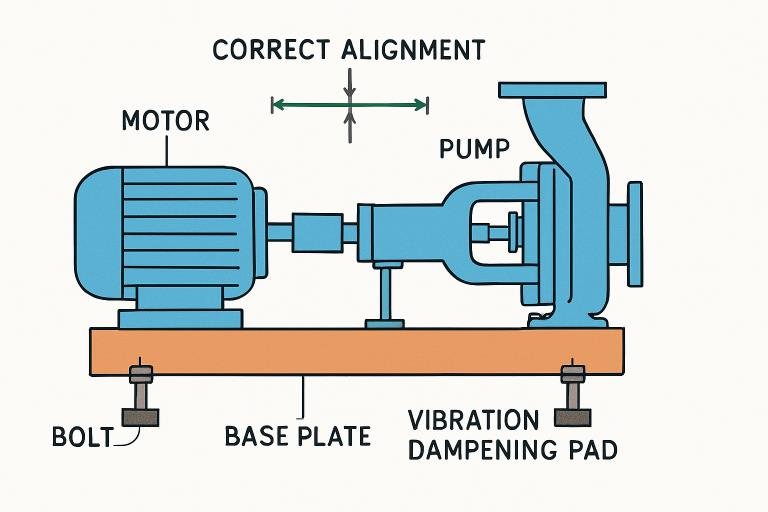

Successful pump base installation begins with thorough preparation and site assessment. This includes analyzing foundation conditions, checking for level surfaces, and confirming access for installation crews and equipment. Anchoring the base is the next critical step, typically involving grouting, bolting, and ensuring vibration-dampening pads are used where required.

Precise alignment is vital—a misaligned pump can lead to shaft and bearing failures, excessive energy consumption, and even catastrophic breakdowns. Technicians employ a combination of dial indicators, shims, and laser alignment tools to achieve optimal positioning. Post-installation checks, such as torque verification, vibration analysis, and flow tests, ensure the base and pump perform as designed. Avoiding shortcuts at this stage is essential: overlooked details here can propagate costly issues downstream.

How Proper Installation Reduces Maintenance Costs

Investing time in high-quality pump base installation yields measurable reductions in ongoing maintenance. Data from industry studies demonstrates that well-aligned, properly anchored pumps can reduce maintenance costs by up to 50%, with some facilities reporting a doubling of mean time between failures. Facility case studies underscore how life cycle costs are dramatically lowered due to fewer unplanned shutdowns, decreased part replacements, and improved energy efficiency.

These best practices are widely documented and constitute general best pump maintenance practices. Following standardized guidelines, such as those from the Hydraulic Institute and leading equipment manufacturers, ensures sites maximize their return on investment and avoid common installation pitfalls.

Signs of a Poor Pump Base Installation

Warning signs of an inadequate pump base installation include unusual noise or vibration, frequent seal or bearing replacements, and uneven wear on pump components. Other indicators—such as excessive heat in couplings or slight base movement during operation—often precede serious equipment failure. These issues can also increase energy use as pumps work harder to maintain expected output, diminishing both efficiency and the longevity of downstream equipment.

Maintenance crews should watch for such signals during inspections, as prompt correction of installation errors can mitigate compounding damage throughout the system. The long-term risks of neglecting these warning signs can be extensive, increasing overall system downtime and expense.

Modern Tools and Technology in Pump Base Installation

Advances in tool technology have revolutionized pump base installation and subsequent maintenance. Laser alignment systems, for example, provide unparalleled accuracy in setting horizontal and vertical alignment, drastically reducing installation time and the likelihood of operator error. Vibration and thermal imaging tools now support predictive maintenance, enabling teams to detect subtle operational changes before they escalate into system failures.

Integrating Industry 4.0 platforms into pump management systems allows for remote monitoring and condition-based maintenance. These digital advancements provide facility operators real-time data, helping preempt costly repairs and optimize overall plant operations.

Comparing Installation Approaches: DIY vs. Professional

Some facility managers may be tempted to treat pump base installation as a modest DIY project for cost savings. However, the stakes in terms of safety, system reliability, and total ownership costs should prompt a careful evaluation. Professional installation teams bring specialized knowledge, tools, and adherence to strict safety protocols, minimizing the risk of errors and compliance issues.

Over the long term, professionally installed bases maximize pump lifespan and minimize downtime, far outweighing any short-term savings from in-house approaches. Facilities that attempt installations in-house often encounter alignment issues, improper anchoring, or overlooked preparation steps—resulting in increased costs and operational disruptions.

Long-Term Gains from High-Quality Installation

Prioritizing high-quality pump base installation produces substantial benefits: improved facility uptime, lower maintenance costs, reduced energy consumption, and more consistent equipment performance. The foundation of every reliable and efficient pump system rests on meticulous installation standards and material selection. By adopting best practices and leveraging modern technology, facilities ensure that their pumping infrastructure delivers long-term value and resilience.

For organizations seeking to future-proof their operations, investing in robust installation and relying on reputable industry partners is not optional—it’s essential for achieving operational excellence and maximizing return on investment.