Environmental testing chambers play a crucial role in the development and validation of products across various industries, including automotive, aerospace, electronics, and pharmaceuticals. By recreating extreme environmental conditions, these chambers help manufacturers ensure product durability, compliance, and long-term reliability. With rapid technological advancements, today’s chambers are more efficient, intelligent, and sustainable than ever before. To explore leading innovations in temperature and environmental testing technologies, visit Associatedenvironmentalsystems.com for comprehensive solutions that meet the demands of modern product testing. Industry leaders are prioritizing energy-efficient and eco-friendly test chamber solutions, which enhance compliance, lower operational costs, and bolster sustainability efforts. As testing methods advance, organizations must adapt to remain competitive. The growing demand for high-quality products drives innovation in environmental testing, yielding significant benefits for industries dependent on accurate testing environments.

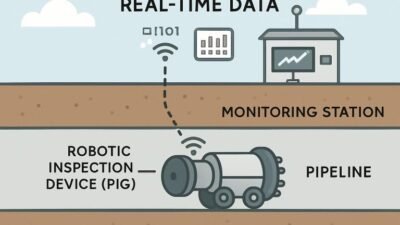

Integration of IoT and Automation

The incorporation of Internet of Things (IoT) platforms and intelligent automation is redefining the way environmental test chambers operate. IoT capabilities allow for real-time data capture, remote chamber monitoring, and streamlined workflow management. With IoT integration, test chambers can collect and analyze operational data continuously, detecting anomalies and enabling predictive maintenance before minor issues become major setbacks. For example, modern IoT-enabled environmental chambers, such as those offered by industry leaders, support seamless connectivity, allowing for the management of multiple test environments from a single dashboard—maximizing efficiency, reducing downtime, and enhancing test result consistency. Automated systems are now equipped with advanced sensors and cloud-based data systems, enabling engineers to remotely adjust testing variables or program chambers to replicate diverse environmental conditions around the clock. This digital transformation minimizes human error, increases throughput, and helps organizations manage global testing programs more cohesively.

Energy-Efficient Solutions

Reducing energy consumption is not just an operational priority—it’s also a growing regulatory and environmental requirement. Today’s energy-efficient test chambers utilize advanced insulation techniques, optimized air circulation, and variable frequency drives to minimize energy waste. Smart control systems dynamically adjust power consumption in response to real-time changes in chamber load and environmental conditions, making each test as resource-efficient as possible. Leading manufacturers report that these advancements can reduce energy use by as much as 30%, without compromising the accuracy or consistency that product testing requires. These savings support sustainability goals while delivering tangible reductions in utility expenses, making new-generation chambers an investment in both environmental stewardship and operational efficiency. Energy-smart industrial systems also contribute significantly to reducing greenhouse gas emissions.

Customization and Modular Designs

As no two testing requirements are identical, customization has become standard for environmental chamber manufacturers. Flexible, modular chambers allow organizations to interchange components for testing various attributes—such as humidity, temperature, UV exposure, or vibration—in a single unit. This approach ensures that each test meets specific regulatory standards and product needs, while reducing overall testing time and maximizing floor space. Modular test chambers can be quickly reconfigured or scaled to accommodate new test protocols or product sizes, providing a future-proof solution for R&D labs dealing with ever-shrinking timelines. This adaptability means manufacturers can meet evolving industry standards without the need to invest in entirely new infrastructure.

Advanced Materials and Sustainability

The push toward sustainability in manufacturing also extends to environmental test chambers. Recent chamber models are built with CFC-free refrigerants and halogen-free insulation to minimize their impact on the planet. Using corrosion-resistant, durable materials, such as aluminum linings, enhances longevity and reduces maintenance needs, which further lessens resource use over the equipment’s lifetime. By prioritizing sustainable manufacturing and renewable materials, leading suppliers contribute to their companies’ larger environmental, social, and governance (ESG) goals. Environmentally friendly designs underscore a commitment to reducing waste and emissions—objectives that are increasingly required by regulators and partners in their supply chains.

AI-Driven Monitoring Systems

Artificial intelligence is reshaping monitoring and operational efficiency within environmental testing. AI-powered controllers can analyze data trends, optimize compressor cycles, and adjust fan speeds in real time, maintaining optimal chamber conditions while using the least energy possible. These predictive algorithms leverage historical data to anticipate necessary adjustments, thereby further enhancing accuracy and reliability in every test cycle. For manufacturers, AI-driven monitoring translates directly to improved product quality and testing throughput, as systems can flag deviations and alert staff before significant issues arise. With this deep learning capability, organizations can minimize waste, reduce re-testing, and ensure strict adherence to regulatory standards.

Compliance with Regulatory Standards

Strict regulatory compliance is non-negotiable for industries such as aerospace and medical devices. Environmental chambers play a fundamental role in simulating adverse weather and transportation conditions, ensuring that products meet established benchmarks for safety, durability, and functionality. Regular updates to international standards further necessitate using cutting-edge chambers with automated documentation and traceability tools. Staying compliant requires regular validation and calibration routines—processes that next-generation chambers can now automate, easing regulatory audits and facilitating easier certification across borders.

Future Trends in Environmental Testing

The environmental chamber market is forecasted to expand steadily, driven by demand for quality assurance, innovation, and the increasing need to ensure product durability for global markets. The adoption of machine learning, enhanced connectivity options, and new materials will further streamline reliability testing, reduce costs, and accelerate product development cycles. As businesses strive to comply with increasingly stringent regulations and more demanding end-user expectations, investment in advanced testing infrastructure is expected to rise accordingly.

The ongoing innovation in environmental testing chambers stands as a cornerstone of quality assurance, regulatory compliance, and sustainability. As capabilities continue to expand, companies that leverage these advancements will be well-positioned to produce robust, reliable products that meet and exceed market expectations for years to come.